13 Nov 2011

So, You Love Timber Frames…

I do, and have for a long time, and I finally got up the nerve to take the plunge and try to build one. This subject can not be covered well in a single post so I’ll link additional posts as I get them finished. I have a lot more to learn, and plenty more to do before the first project is complete. It is my hope that you’ll follow along, enjoy the journey, and if you have the notion to build one of these lovely structures perhaps this will encourage you to press forward.

The picture above was taken in Eltville Germany, a small town along the Rhine RIver near where I lived for several years. Seeing these buildings with cornerstones pre-dating the founding of our country seeded my mind with thoughts of the possible.

Have to say up front that part of my delay getting started was intimidation factor. This project represents a pretty big bite in terms of commitment, time, and skill. Timber frame construction has been described as cabinet making on an architectural scale. That description brings to mind fine woodworking skills multiplied by a difficulty factor measured out in wood fiber by the ton.

As we get started, let me share a quote with you that makes me smile when brought to mind and is particularly appropriate for a project like this: “It’s been a good day in the shop when you need a shovel to clean up the shavings and saw dust.” Author Unknown (to me).

Is it Really Possible?

As if that’s not enough, there is the issue of collecting all that wood fiber in the appropriate form factor. Last time I checked the local home improvement centers aren’t carrying 6x9x10′ oak timbers. Oh, and throw in 3x4x10′ pine fascia beams, 4×6 locust sills, and 3×10 tapered rafters.

Backing up one more step, where do you get the design for one of these things anyway?

Well, definitely an elephant, lets see if the old adage that he’s edible, one bite at a time is true.

A Master Plan

Well, an overarching plan is definitely in order. Where to start? How about some brainstorming to focus on what is required: selecting a building style, completing a design, finding a source of materials, collecting tools, and developing skills to execute the design.

The first big drop that fell out of that storm was that it’s really all all about learning: a bunch of stuff. Taking a little time to break down the list revealed what seems like a logical sequence that tracks the build order, it’s mostly serial. Elephant steaks! So what are these morsels? Lets take a look at the curriculum….

Understanding Style & Design

The next drops are twins in my mind: Building style and design. The combination of these two attributes are fundamental to the architectural style of of timber frames. A structure is a timber frame, by definition, when it is composed of ‘bents’. These frames are typically a cross section of the building and are often one timber long and are placed along the length of the structure to define the enclosed space.

An integral part of the design comes from the choice of joints used to attach the timbers to each other creating the frame. There are hybrid designs that use steel in the joint but what most interests me are traditional joints made exclusively with wood. Common joints are mortise and tenon, dove tail, and scarf to name a few.

Style and design form part of the foundation that make up a timber frame structure, but how to learn at least enough to successfully move forward? From what I have been able to find Tedd Benson and Jack Sobon have done the best job getting practical, hands on details about timber frame building into book form and are critical resources to learn about this fascinating subject. I have included affiliate links to these books below for your convenience should you care to learn more.

Where to get the Beams

The next squall from the brain storm coalesced around the third defining attribute of timber frames: big wood. The “timber” in timber frame. In case the picture doesn’t give it away let me say that this is heading straight to my very own saw mill. It’s probably fair to say that I was driven to this method of material acquisition by a perfect storm.

I would like to blame the whole thing on a personality defect. For what ever reason I have the hardest time buying things over and over when the possibility exists to create them myself. In this case the thing I imagine buying repeatedly is expensive, hard to find timbers, and the solution is, well, you know…

It doesn’t help that I have cleared bunches of trees lost to storms and disease for friends throughout the years. The thought that always comes to mind as I cut and burn cord after cord of lovely oak, beach, pine, and locust is “there goes a bunch of fine lumber”. Combining all this with a new need for beams was just too much, and the out come was rather predictable

Tools, Wonderful Tools

Next come the tools. There is good news here, not a lot of specialized or expensive power tools are required. What is needed are squares, levels, hand saws and the like. I do think that a framing chisel (or three 🙂 are in order, but other than that it’s all things that are commonly available.

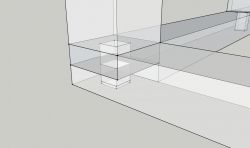

Let me mention a tool that I didn’t even consider at first: 3d modeling software. Thank goodness for all those bright folks at Google who created and gave away Sketch Up. This 3d visualizer, combined with TF Rubies from Clark Bremer are so useful I would put them at the top of the list of tools. And the best thing they are just a download away.

Of course there are always things you can buy….

Skill Development

The final, and most important leaning area is skills development. Having a great plan, beautiful design, appropriate joints, and the right tools will not yield a sound building without some skill in execution. It’s all about practice, discipline, and paying attention to details. I am taking baby steps on this point so I don’t have a whole lot to write about yet.

I have completed a very basic post and beam shed some years ago and am now in the process of extending what I have learned a bunch. Making cuts with the saw, drilling holes, chiseling out mortises. Nothing revolutionary. I am coming to the conclusion though some of the most interesting lessons may not be the thing I can post in an article. Rather, it has to do with flow and feel of the tasks at hand.

So what are you waiting for, get out there and do it!

Footnote: here are a couple of books I have read and found to be helpful. The links will open a new window and are from the affiliate program at Amazon so if you purchase by following them I will receive a small referral that will be used to for site content development and maintenance.

. .